|

PROTOS Engineering Euro - Consultants Ltd |

|||||

|

||||||

|

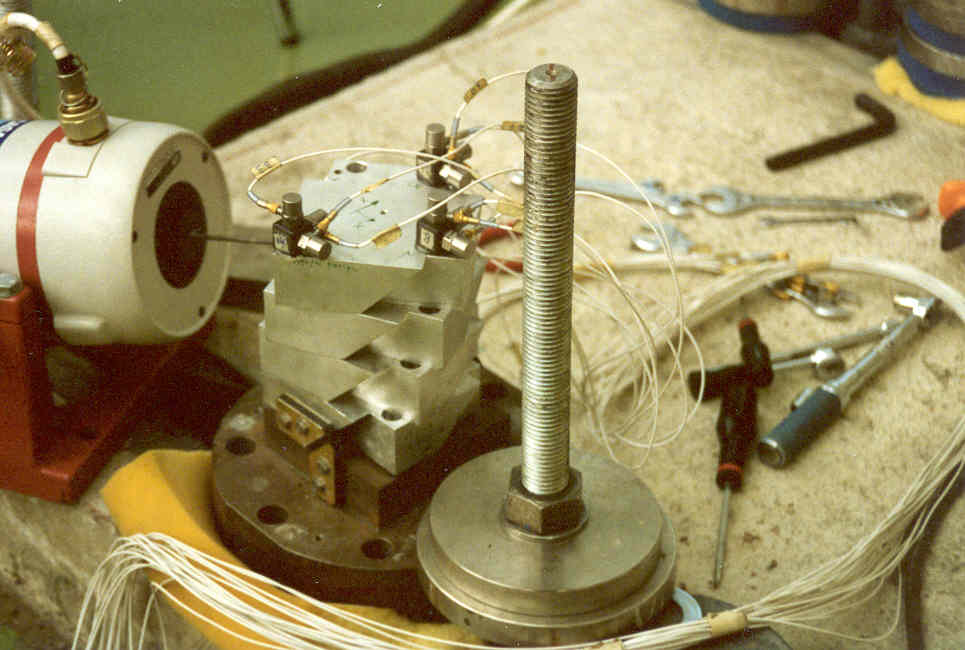

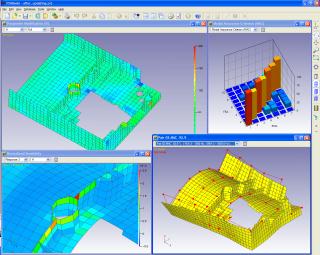

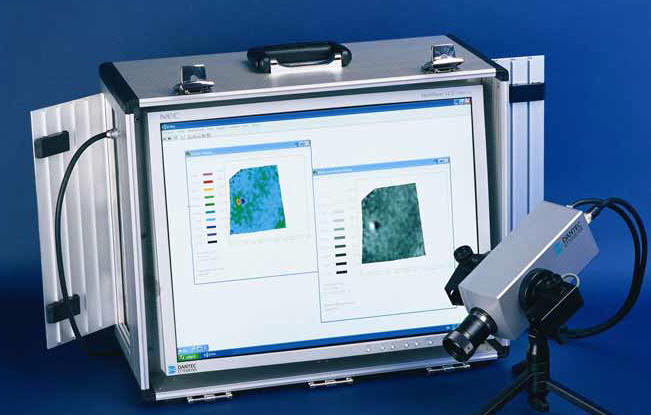

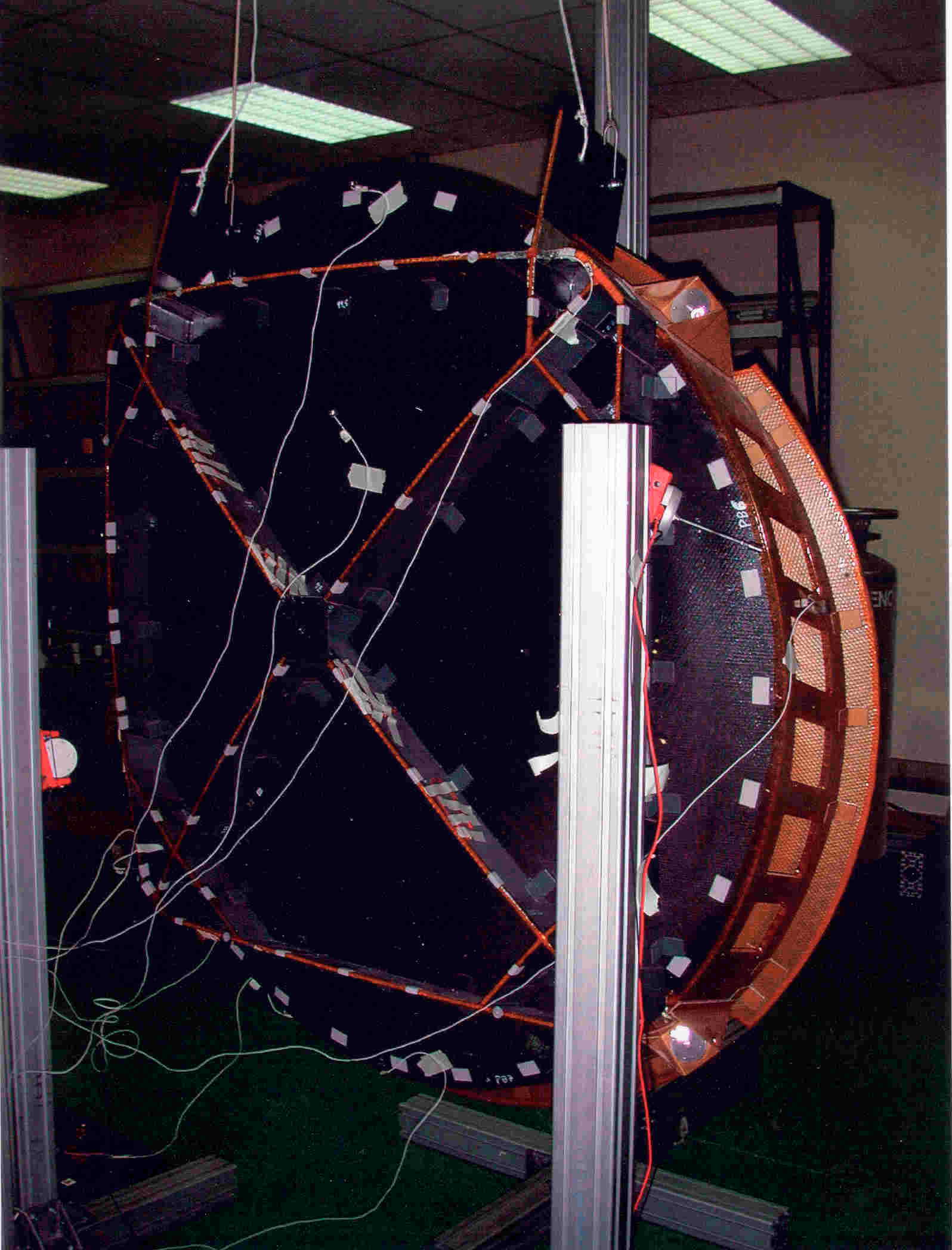

ENGINEERING CONSULTANCY SERVICES TEST PROTOS can perform specific Dynamic and Static tests on new Prototype structures as part of Design Verification or Trouble-Shooting tasks. These tests aim to measure the mechanics ( Dynamic or Static properties ) of the structures. The measured properties are then used to verify and if necessary update the predictive quality of the existing models of the tested structure. This verification of the models is an essential requirement for the models to be "trustworthy" for use in further predictive analysis and Design changes. The following is a list of some of the Tests performed : Modal Test : A dynamic test used across all the industries in order to measure the inherent normal mode vibration characteristics ( Resonant Frequencies, Mode Shapes, Modal Damping, Generalised Parameters) of the test specimen. Static Test : The mechanical properties of the structure under statically applied loads is measured in order to derive the response levels under specific loads ( stiffness ) or the loads that cause breakage ( fracture ). Operational Test : Measurements ( accelerations, strains, pressure levels, etc) are obtained under normal operational conditions. This way more realistic dynamic properties of the structure are obtained and are used to qualify new designs or trouble-shoot existing problems. Acoustic Test : The newly designed structure ( usually those containing panel like components ) are exposed to acoustic excitation in specially prepared enclosures. The dynamic responses ( acceleration, strains, etc) are measured and used for new design qualification or trouble-shooting tasks. Hybrid Noise Reduction Test : A campaign of systematic test measurements involving structural and acoustic excitations and measurements on structures that usually contain enclosed cavities e.g. vehicles. The exploitation of the modal and acoustic inherent parameters of the structure coupled with the structural and acoustic measurements is used in identifying the sources of unacceptable vibro-acoustic problems in the structure. Once the sources are identified the vibro-acoustic models are used to change the design and guarantee problem elimination. Vibration Test : These qualification ( otherwise known as pass / no pass) tests involve installing the structure on large electro - dynamic ( or servo -hydraulic ) shakers and vibrating them. The vibration is reproducing the dynamic environment that the structure will have to survive during its service life. Effectively if the structure survives this real simulation of the service environment, it is said to be qualified and be ready to manufactured and introduced in the market. Functional Test : This type of tests is usually obtaining measurements and at the same time qualifying some specific function of the structure that is simulating real time operation. A release mechanism of a satellite deployment process or the application of the brakes in a vehicle and the resulting dynamics are some typical examples of this type of test. Mathematical Model Updating The work involved in this area is possibly the most crucial in the whole Computer Aided Design process of a new product. Once Mathematical Model Simulations and Response Predictions are available they can be used as Virtual Prototypes to help optimise the design of the product and accelerate its introduction to the market before the competition product gets there. Even with the state of the art of computers and highly trained Analysts mathematical models need verification and most of the times corrections. This so called Model Updating process is based on comparisons (Correlation) of the model predicted responses with those measured from tests. Based on the Correlation results an Updating of the model is called for. This Updating can be a time consuming and experience demanding process. A precisely updated model however can be used as a Virtual Prototype that can be used to optimise the Design and eliminate possible structural failures. Structural Qualification Campaigns Effectively here PROTOS undertakes responsibility of the whole product qualification process. The client provides PROTOS with the engineering drawings of the structure and possibly any available prototypes. PROTOS then carries out all the various tasks involved in the CAE qualification of the new product and returns to the client the updated and optimised Design that is guaranteed to produce a structure that will survive its operating environments and will provide an optimum Vibro - Acoustic performance during its service life. |

|

|||||